ETCO Plate-tube Evaporative Condensed Chiller板管蒸發冷卻式冷水機

ETCO Plate-tube Evaporative Condensed Chiller uses the latest evaporative condensing technology for direct cooling of refrigerant of the chiller. It is a highly energy efficient alternative to the air cooled and water cooled condensed chillers, with saving of energy over 35% and 15% respectively.

The Chiller bases on the patented Plate-Tube Liquid Film Evaporative Technology to provide cooling of condenser by direct spray of water on the condenser so then the cooling effect of the system is highly improved. It is the most efficient cooling technology at present. This technology practices the combination of the merits of the following Refrigeration Systems :

- Compact/Simple design of Air-cooled System

- High refrigerant effect of Water-cooled System

板管蒸發冷卻式空調,主要是用最新的蒸發式冷凝技術作為冷卻空調雪種之用。它的高效能特性較目前一般應用的風冷空調系統和水冷空調系統相比比較,可節能分別35%及15%以上(見p.7)。 創新專利的板管平面液膜蒸發技術,通過熱交換系統,直接獲得接近於濕球溫度的冷卻水溫度,為大功率的冷卻水系統提供了高效能的傳遞效應,節省大量能源, 是目前最高能效的製冷技術。此技術結合了下列冷凍技術的優點:

- 風冷式冷水機組的緊密和簡單結構

- 水冷式機組的高製冷效率

Plate-tube Evaporative Condensed Chiller Working Principle板管蒸發冷卻式冷水機工作原理

Plate-tube Evaporative Condensed Chiller adopts the patented plate-tube evaporative condenser technology. It makes use of air and water as the cooling medium with the water removes the heat from condenser when water evaporates. The cooled water is pumped to the top of condenser and sprayed onto the plate-tube surface as a thin water film. The hot refrigerant gaseous enters from the top of condenser and then exits at the bottom as cooled liquid refrigerant. The heat is absorbed by water film and then be evaporated and removed by fan with air velocity ranging between 3-5 m/s. This high speed air flow increases the efficiency of heat transfer rate. The remaining water is blocked by the water retaining plate and falls into the collection basin for re-circulation.

板管蒸發冷卻式水機是將冷凝器和冷卻水塔合二為一, 直接發揮水的蒸發潛熱冷卻工藝流體。它是以水和空氣作冷卻介質, 利用水的蒸發帶走氣態製冷劑的冷凝熱。工作時冷卻水由水泵送至冷凝管組上部噴嘴, 均勻地噴淋在冷凝板管外表面, 形成一層很簿的水膜, 高溫氣態製冷劑由冷凝板管組上部進入, 被板管外的冷卻水 吸收熱量冷凝成液體從下部流出, 吸收熱量的水一部份蒸發為水蒸氣, 其餘落在底部的集水盤內, 供水泵循環使用, 風機強廹空氣以3-5米/秒的速度掠過冷凝板管促使水膜蒸發, 強化冷凝板管外放熱, 并使吸熱後的水滴在下落的過程中被空氣冷卻, 蒸發的水蒸氣隨從空氣被風機排出, 仍未蒸發的水滴被脫水器阻擋跌落回水盤。

The Chiller not only physically integrates the condenser and cooling tower to form a compact refrigeration system with built-in condenser pumps to simplify the air-conditioning water circulation system and improve the system efficiency, but also incorporates a number of advanced and patented technologies to further enhance the effectiveness of the chiller, includes :

- Patented Plate-tube Liquid Film Evaporative Technology

- Corrosive-resisted Hot-dip Zinc Treatment

- Highly Efficient and effective Drift Eliminator

- ECA Ultraviolet Disinfection System

板管蒸發冷卻式冷水機 不但結構上將冷凝器和冷卻水塔合二為一,充分利用水的蒸發潛熱冷卻工藝和簡化冷凝水循環系統,將能效比提高,更另引入多項專利和嶄新科技,將冷水機之效能和衛生安全再大大提高,包括:

- 平面液膜蒸發技術 (專利)

- 熱浸鋅特殊工藝處理

- 高效能漂水消除器

- ECA紫外光殺菌除垢系統

How ECA chiller works

Patented Plate-tube Liquid Film Evaporative Technology板管平面液膜蒸發技術 (專利)

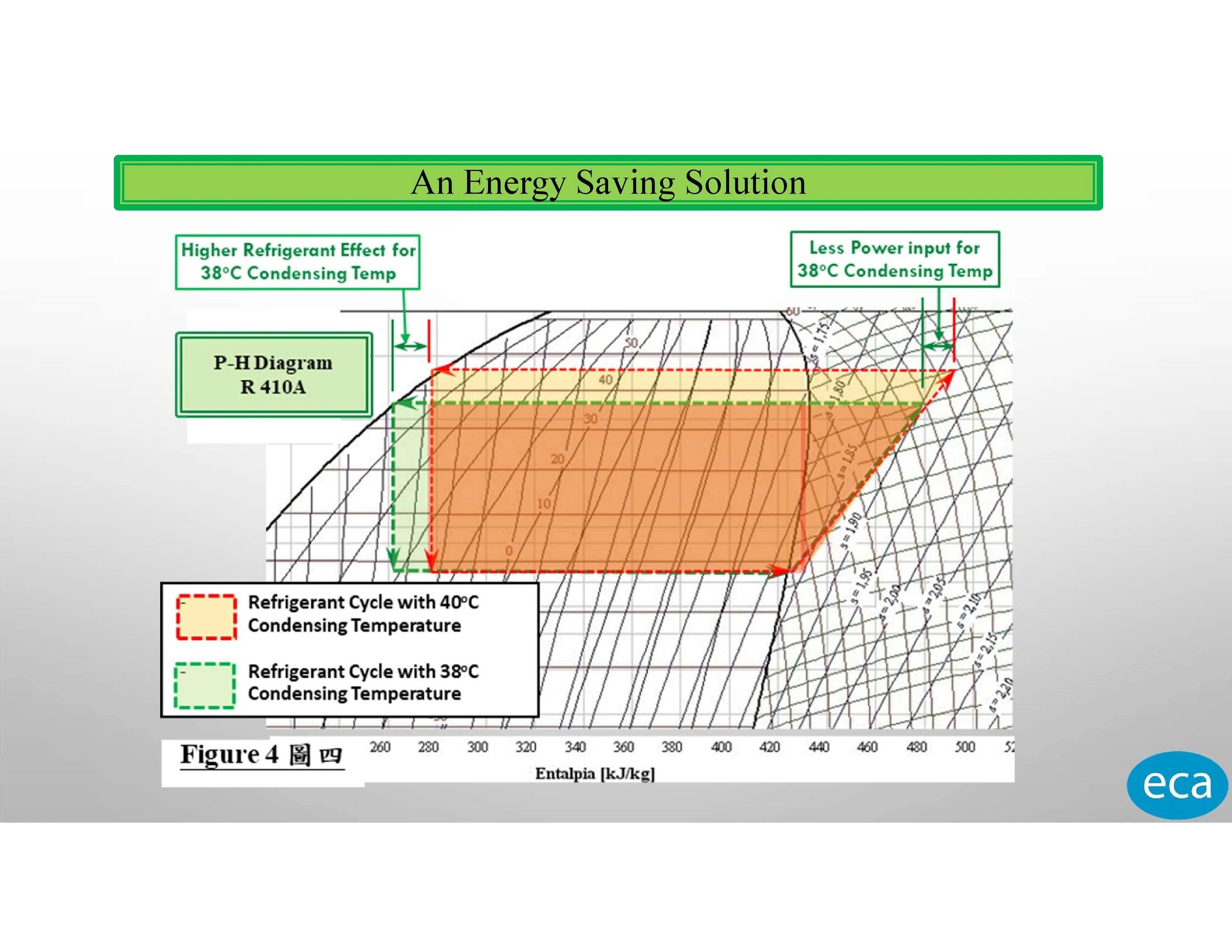

Patented Plate-Tube Liquid Film Evaporative Technology (Figure 2 & 5) is used to replace the traditional tube type evaporative condenser. It is the highest efficient condenser with lower condensing temperature (38℃) as compared to air cooled (48℃) and water cooled (40℃). The heat transfer rate of the condenser can be greatly improved and prolong the working life of the equipment. Besides it minimizes the presence of scale and sludge on surface of the condenser.

板管平面液膜蒸發技術的冷凝器(圖二)是用作代替一般盤管冷凝器用作冷水機雪種之運行,普通風冷式的冷凝溫度為48∘C,水冷式的冷凝溫為40∘C,而板管蒸發式的冷溫度在38℃以下(見p.7),壓縮機功耗更小,其他條件相同,更低的冷凝溫度時製冷量更大,COP更高,這對壓縮機運行更穩定,使用壽命更長。此外這技術亦大大減低外管垢之產生,把平面液膜蒸發冷凝器之導熱效能進一步提高及減低維修費用。

Pressure Enthalpy Chart

Corrosive-resisted Hot-dip Zinc Treatment熱浸鋅特殊工藝處理

ETCO Plate-tube condenser is made of corrosive resistant material with special hot dipped zinc coating to enhance the anti-corrosive and calcium solubility properties of the condenser to ensure stable operation of the chiller by scale & sludge reduction.

ETCO 板管蒸發式冷凝器採用超強耐腐蝕的高導熱性複合金屬材料,並進行熱浸鋅特殊工藝處理, 板管蒸發冷凝器的冷凝溫度在38℃以下,低的冷凝溫度,鈣離子的溶解度更高,冷凝器的防結垢性能更好,加上全覆蓋噴淋換熱形式,能有效防止板片結垢,從源頭上解決冷凝器結垢問題,使製冷系統運行更穩定,更加耐用。

Highly Efficient & Effective Drift Eliminator高效能漂水消除器

The tailor-made Drift Eliminator is installed in the chiller to ensure the Drift Rate of the chiller is less than 0.005% of the maximum limit of water circulation rate (Statuary Requirement- Code of Practice for Fresh Water Cooling Towers - 2016 Edition).

板管蒸發器採用專用高效能漂水消除器有效地把每一滴水用於蒸發潛熱冷卻功能,以確保漂水率低於運水量之0.005%的法例要求(機電工程署-淡水冷卻塔計劃-2016 版)。

Built-in ECA Ultraviolet Disinfection System 內置ECA紫外光 殺菌除垢系統

ECA Ultraviolet Disinfection System equipped with Water Treatment Device is specially designed for “ETCO” Chiller for the sterilization of the system to ensure the hygiene of circulation water without Legionella and increase the penetration effect of the water to minimize the creation of pipe scale and sludge.

ECA紫外光自動殺菌系統內置高能量活水器是特配”ETCO”板管蒸發冷卻式冷水機而設,主要消除水箱內的退伍軍人桿菌和一般菌藻類的滋生及提高水的滲透性和磁滯效應,清除冷凝器和喉管內的阻垢聚積,延長冷凝器壽命及減少維修理費,集一體化設計,省地方,又衛生。